Working process of shrink packaging machine

Working process of shrink packaging machine

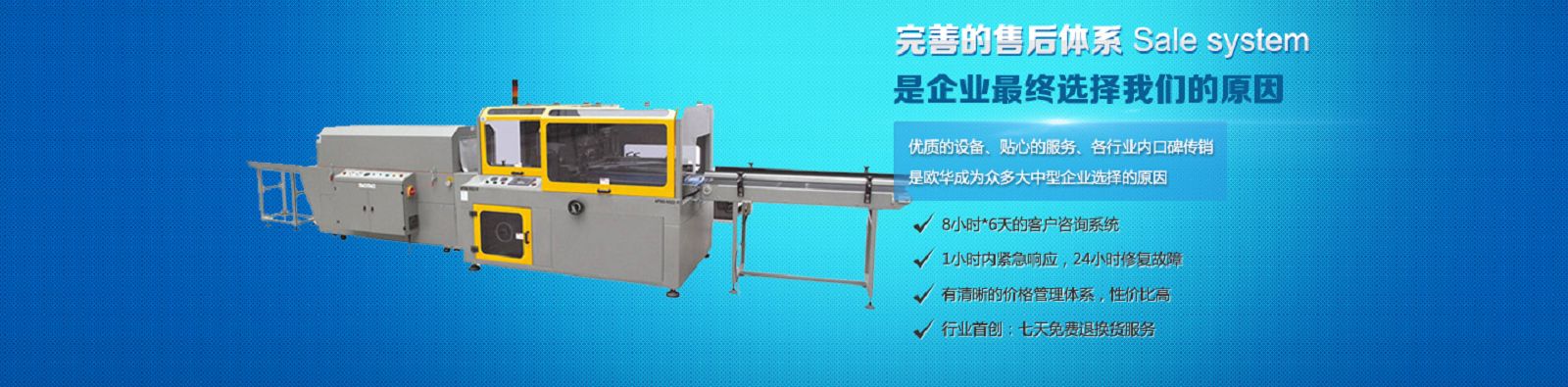

Full automatic bag packaging machine is the most advanced and the highest degree of automation in the heat shrink packaging machine. The product is suitable for film sealing and heat shrink packaging. Full automatic heat shrink packing machine can automatically send the film, then automatic bag forming, surface smooth, seal cutting film packing, heat shrinkable packaging a complete. At the same time the waste can be recycled. The cutter of the automatic heat shrinking machine is a constant temperature type aluminum alloy material, which is specially designed for the POF diaphragm sealing and cutting. The cutting knife is characterized in that the sealing line is relatively thin, and the anti adhesion. In addition, for the case of different packaging sizes, the automatic heat shrink packaging machine can be adjusted within a certain range, no need to replace the abrasive tools. At the same time can manually adjust the location as there is heat shrink furnace temperature and heat shrink packaging speed. The product is widely used in pharmaceutical, food, stationery, cosmetics, electronic products, toys and other fields. First to bag packaging machine set heating time press the manual or automatic button, the rack cylinder solenoid valve to electrical output driving gear, the gear drives the chain, then rack cylinder bit proximity switch. When the rack cylinder runs to the top dead point, the front position of the rack cylinder is close to the switch, and the electric output of the electromagnetic valve of the oven cylinder is electrically operated. When the oven cylinder runs to the top dead point, the timer (see figure below) starts the start time delay, and the rack cylinder solenoid valve is off. Timing end, oven cylinder solenoid valve power.